upFront.eZine #1,111: The State of STEP

With Martin Hardwick (STEP Tools), Neil Peterson (Open Design Alliance)

Inside the Business of CAD | 1 November 2021

There was no need, in the early days of mechanical CAD, to exchange files. MCAD was rare enough that it did not matter that systems were incompatible. But by 1976, MCAD had become common enough for the US Air Force to demand a way to reduce costs associated with moving files from the design floor to manufacturing contractors. The solution was found in a common format named “initial graphics exchange specification” — IGES, for short.

From IGES to PDES to STEP

IGES became verbose and unwieldy as over time it supported more and more data types specific to the increasing number of MCAD systems. In Germany, the automotive industry came up with its own widespread standard for exchanging surface data of the skins of automobiles, VDA-FS. What was needed as a modern replacement.

So the IGES Steering Committee began work on a new file format, PDES (product data exchange specification), to do a better job at defining an all-encompassing format: “PDES is envisioned to support all aspects of product description, from initial conception through product design, manufacture, support, and disposal,” said the US Department of Commerce, sounding a lot like PLM today.

In 1985, the committee contributed PDES to an ISO initiative that was creating a universal file format flexible enough to handle “anything from a microchip to a battleship.” This became known as STEP, the “STandard for the Exchange of Product model data.”

STEP was an extensible format, one that could be extended as new technology came along. It handles inheritances, such as a spoke inheriting the properties of the steel wheel in which it resides. Definitions are determined by an object-oriented data programming language, EXPRESS.

The first release of STEP came out in 1995. Sometimes you also see it referred to as “AP203” (short for application protocol level 2). Today, STEP consists of 800 standards (see figure below), of which four are for end users, with the remainder a library of reusable definitions.

AP203 for solid models (1995)

AP214 for assemblies (2003)

AP242 for annotations (2015)

AP242e2 for tolerances (last year)

To learn where STEP is headed next, I spoke with Martin Hardwick, CEO of STEP Tools, and Neil Peterson, president of the Open Design Alliance.

STEP for Machining

The original purpose of IGES was to make it easier for manufacturers, like General Electric, to deal with 3D models arriving from suppliers using incompatible MCAD file formats. The process looked like this, and today still looks a lot like this:

CAD operator makes drawings with no regard for the manufacturing process

CAM operator designs the manufacturing process

Postprocessor in CAM software generates the G-code that instructs the machine

CNC operator closely supervises the machining to make sure the initial parts were made correctly

The desire today is to go direct from CAD to CNC, Martin Hardwick told me.

CAD operator makes the 3D model suitable for manufacturing

Postprocessor in CAD makes the STEP-NC file

CNC machine uses STEP-NC for automated, optimized machining (see figure below)

STEP has been extended to parts machining, where it is known as STEP-NC (numerical control):

AP238 version 1 for precision machining (2005)

AP238 version 2 for precision assembly (last year)

It was the addition of AP242e2 tolerances that allowed STEP to expand into automated manufacturing. When you know the tolerances that manufacturing needs to meet, you can machine parts to those tolerances. Before this, machines controls worked blindly, not knowing what was allowed.

There is complexity inherent in CAM. “Before, the operator figured it out; now software has to be rewritten to figure it out,” said Mr Hardwick. The change means a massive rewrite of CAM software, something not all firms can afford. Partly as a result of this industry change, many CAM firms — like Cimitron, GibbsCAM, MasterCAM, SigmaNEST, and Vericut — have in recent years sold themselves to larger companies, like Sandvik.

Year by year, STEP-NC is adding more to the process data needed to know how to mill, drill, or lathe a part, how to lead in, the speed at which to run, and so on. The key is to know which operations have to be done in which order with the minimum viable tool path. When the data is rich, intelligent software on the controller should be able to figure out the rest.

Each year since 2017, STEP-NC has been used to machine millions of 5-axis parts for commercial aircraft, such as the Boeing 787. Now STEP-NC is being prepared for direct-CAD-to-CNC 2.5-axis milling for features on airframes. As well, it is getting ready for 3D printing, leading Mr Hardwick to call STEP-NC “the PDF of machining.”

ODA Expands to STEP

The Open Design Alliance develops code, such as for reading and writing DWG and PDF files, that is used commercially by its CAD software member companies. By developing the code on behalf of them, the 1,200 members don’t need to develop it themselves.

Five years ago, the organization expanded its offerings dramatically. It moved from offering individual SDKs (since 1998) to a complete technology package for working with CAD and BIM files, including Web collaboration, version control, and visualization on any platform, supported by a natively developed solid modeler and constraints engine.

Then earlier this year, the ODA announced support for STEP based on a strong demand from ODA members, because existing STEP libraries are expensive and are royalty-based, ODA president Neil Peterson told me in an interview. In some cases, STEP is not licensed as an individual component; rather it is bundled with a larger group of converters. Some libraries are in the public domain, but suffer from insufficient development. So there is no economical, high-quality library on the market that’s affordable for small firms, he said.

Some ODA members just want access to STEP files. Other members, who make use of the ODA’s IFC APIs for architectural design, want both: IFC for building designs, STEP for machinery that goes inside the buildings. ODA is taking on STEP support as a long-term priority.

With STEP files and the EXPRESS programming language being hugely complex, I wondered how the work could get done so fast. PDES, after all, had been working on the problem for nearly three decades.

“We gained expertise by developing IFC,” said Mr Peterson. “Similar to IFC, STEP is defined using EXPRESS schema, and so we can reuse the automation framework we developed for IFC to quickly build a high-quality STEP solution.” As well, the ODA is a member of PDES, the group that maintains the STEP standard, just as it works with buildingSMART on IFCs. From PDES, the ODA gets test data and works on committees that establish extensions to the standard.

The ODA’s timeline looks like this:

By the end of this year, it plans to release an initial version of the STEP SDK (software development kit) with read/write support for AP203, AP214, and AP242 (all conformance classes).

By the end of 2022, the ODA plans full visualization support for the same three APs running on desktop, mobile, and Web, including a free-to-all, commercial-grade STEP viewer similar to the ODA’s IFC and DWG viewers.

The alliance plans to offer publishing of STEP models to 2D/3D PDF, and conversion of STEP to formats, such as Navisworks and DWG.

The cost of getting the STEP APIs from the ODA will be “free.” That is, members, who pay an annual membership fee to the ODA starting at $1,800 a year, pay nothing extra once STEP becomes available, and there are no royalty payments involved. This presents the possibility of undercutting other STEP suppliers, such as STEP Tools in USA, EPA in Sweden, and ProSTEP in Germany.

Longer term, the ODA is interested in AP238 STEP-NC, and the conversion of model data to formats like IFC and Revit. Mr Peterson notes that “Priorities in these areas will be based on requests from our members.”

What Ralph Grabowski Thinks

The MCAD/CAM industry needs a universal file format to minimize the cost and inconvenience of translating data between CAD systems, and for the machines that do the manufacturing.

Other industries like AEC/BIM have found, however, that arriving at universality is a terribly complex problem. That’s because every CAD vendor desires to maintain unique advantages over competitors, and so prefers to stay with its unique file formats.

Lip service is given to data interoperability, so while data flows easily into CAD systems, it emerges rather reluctantly. There is, after all, a programmer cost to implementing exchange standards like STEP and IFC, both of which are increasing in complexity as they expand in capability.

The 2020s find the STEP standard expanding in two directions, towards greater complexity with STEP-NC, and towards lower cost with ODA STEP. The toolkits provided by the ODA, one can hope, ought to make implementing data exchange universality in architectural and mechanical worlds easier.

[This article first appeared in Design Engineering magazine and is reprinted with permission.]

And in Other News

Rådgivende Ingeniørers Forening represents 140 Norwegian engineering consulting firms with 500 offices and 13,000 employees. RIF is unhappy with “major software developers hiking up prices by 30% annually with only a few months warning.” The one vendor mentioned is Autodesk, for its disparate country pricing.

The engineering firms lay out an ultimatum: “The industry’s preferred software suppliers in the future will therefore be those who are able to communicate early and well about future pricing policies.” The press release can be downloaded from here: rif.no/wp-content/uploads/2021/10/Open-letter-to-software-developers-for-the-consultant-engineering-industry.pdf.

It seems to me that organizations like hospitals and design firms ought to be forming purchasing pools to negotiate rock bottom pricing from suppliers.

- - -

Nanosoft launches release 21 of nanoCAD as a CAD platform supporting five modules:

3D Modeling — direct, sheet metal, mesh, and parametric 3D solid modeling with 2D/3D constraints

Mechanica — mechanical drawing, engineering calculation utilities, and library of parametric parts

Construction — AEC drafting utilities and library of parametric parts

Raster — (new) import, correct, and vectorize raster images

Topoplan — digital terrain modeling

nanoCAD 21 starts at $200/yr; each module is $150/yr. Permanent licenses are provided with a three-year subscription. nanoCAD 5 is available free. https://nanocad.com/

[Disclosure: I produce training videos for Nanosoft.]

- - -

At the Bricsys conference last week, Hexagon answered the question that puzzled executives when I asked them two years ago: Where does the BricsCAD acquisition fit into Hexagon?

We have the answer from ceo Ola Rollén: For Hexagon to get deeper into the AEC space, and for BricsCAD to get into the discrete manufacturing market.

[Disclosure: I have written books and produced training videos for Bricsys.]

- - -

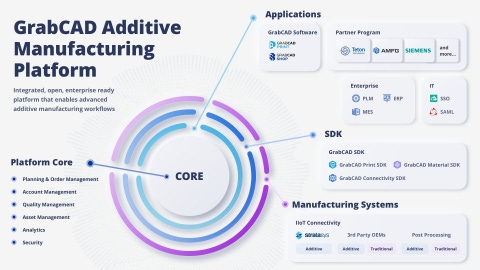

Stratasys turns GrabCAD into a software pipeline for 3D printing (aka additive manufacturing). Its new GrabCAD AM Platform manages multiple 3D printers at multiple locations, monitors output quality, automates materials management, and integrates all this with the enterprise.

The platform is a combination of GrabCAD software, software from partners, and an SDK. Wannabe partners pay an SDK licensing free, following approval. https://grabcad.com

[Disclosure: Following the launch of GrabCAD as a 3D part sharing site, the founder joked he named the site after me.]

- - -

Here is one of the posts that appeared recently on my WorldCAD Access blog:

You can subscribe to the WorldCAD Access blog’s RSS feed through Feed Burner at feeds.feedburner.com/WorldcadAccess.

Letters to the Editor

Re: Online Conference Burnout

For most attendees (at least for non-media, but I suspect also for media) the real value of conferences is the networking and informal discussions that take place during and outside the conference. After attending dozens of AU and a few other CAD conferences for many years in different capacities, it became clear to me that the best conferences are

a) in-person, with at least one or more organized social event

b) small enough that individuals don't get lost in the crowd

c) with wide coverage area (i.e. national or worldwide, not local)

d) including vendors and their cool new tech (plus free swag)

It surely is not easy (nor inexpensive), but if I was running a CAD company I would pounce on the opportunity created by the pandemic to capitalize on the natural human hunger for fellowship.

- Owen Wengerd (via WorldCAD Access)

The editor replies: I suspect the difference between small conferences (which we like) and monster conferences (which we don’t) is that it’s the staff of the small company that puts together the small conference and who are in touch with the needs of users. I’ve had organizers of small conferences ask me what I would like to see.

The giant conferences put on by giant companies are, I am guessing, organized by marketing departments, whose day job is to promote the company. Hence the disconnect.

Notable Quotable

“With a few exceptions, most previously successful founders rarely replicate their success in their second company. Financial success weakens determination and fighter mentality.”

- Don Dodge

Thank You, Readers

Thank you to readers who donate towards the operation of upFront.eZine:

Novedge LLC (small company donation): “Keep up the great work!”

John Brunt: “Thanks for your coverage of BIM issues.”

To support upFront.eZine through PayPal.me, then I suggest the following amounts:

$25 for individuals > paypal.me/upfrontezine/25

$150 for small companies > paypal.me/upfrontezine/150

$750 for large companies > paypal.me/upfrontezine/750

Should Paypal.me not operate in your country, then please use www.paypal.com and use the account of grabowski@telus.net.

Or ask grabowski@telus.net about making a direct bank transfer through Wise (Transferwise).

Or mail a cheque (US$ or CDN$ only, please) to upFront.eZine Publishing, Ltd., 34486 Donlyn Avenue, Abbotsford BC, V2S 4W7, Canada.

Contact!

upFront.eZine is published most Mondays. This newsletter is read by 4,700 subscribers in 70 countries. Read our back issues at www.upfrontezine.com.

Editor: Ralph Grabowski

Copy editor: Heather MacKenzie

Letter the editor are welcome at grabowski@telus.net. All letters sent to the editor are subject to publication, and may be edited for clarity and brevity.

Advertising starts at US$340 per two weeks. Download the media kit from upFront-Media-Kit.pdf. Contact grabowski@telus.net to discuss advertising.

To subscribe, click this link to sign up with with our mailer, Substack.

To change your address, send both your old and new email addresses to me at grabowski@telus.net.

To unsubscribe, click the Unsubscribe link at the end of this newsletter.

*4703

About

Copyright © 2021 by upFront.eZine Publishing, Ltd. All rights reserved.

Legal. All trademarks belong to their respective holders. “upFront.eZine,” “Inside the Business of CAD,” “WorldCAD Access,” and “eBooks.onLine” are trademarks of upFront.eZine Publishing, Ltd. Translations and opinions expressed are not necessarily shared by upFront.eZine Publishing, Ltd. By accessing this newsletter in any manner, you agree to settle disputes within ten days of publication date by arbitration within the city limits of Abbotsford, British Columbia, Canada with the arbitrator selected by an agent acting on behalf of upFront.eZine Publishing, Ltd.

Our mailing address:

upFront.eZine Publishing, Ltd.

34486 Donlyn Avenue

Abbotsford BC

V2S 4W7