Inside the Business of CAD | 11 October 2021

This issue is sponsored by CCE:

EnSuite-Cloud ReVue: Secure Conferencing for Your Online Engineering Meetings

Discuss 2D/3D CAD engineering designs in real-time with your team and suppliers, no matter where they are. No software to install, no proprietary design data left on servers.

Our online meetings support models made in CATIA, SOLIDWORKS, NX, Inventor, Creo, and more.

Start your online meeting for free at cadcam-e.com/EnSuite-Cloud-ReVue.

Solid Edge 2022 began shipping last week, boasting of 500 new functions and improvements. I spoke with Siemens vp of mainstream engineering Dan Staples about the new features I found the most interesting.

New: CAD Direct

CAD Direct inserts CAD parts into Solid Edge assemblies from certain other systems, without translation. Changes made to the model in the originating CAD system are reflected in the copy stored in the Solid Edge assembly.

Ralph Grabowski: I’ll start right away with CAD Direct. It reminds me of the ’90s when Intergraph championed the use of OLE for D&M to place CAD models in other documents without translation. So I’m interested in the mechanism CAD Direct uses today.

[Intergraph patented OLE for Design and Modeling in 1993; the technology never went far, because Microsoft did not implement OLE well. At around the same time, in 1995, Intergraph first released Solid Edge. — Editor]

Dan Staples: OK, yeah, so, funny Ralph, that you should go back so far as the whole OLE [object linking and embedding] craze back in the ’90s. It is an interesting analogy to that.

The CAD Direct technology is not really a Windows technology, per se. I think the key piece of it is our ability to keep an intermediary file inside the assembly, so that you never have any external files.

I think that’s one of the biggest problems with data management. It’s kind of been this untold secret that when you translate a file you end up with a new extra file. When it comes to making an update, you’ve got this new extra file to deal with, right?

With CAD Direct, you don’t have that anymore and it does updates live. It’s all just done using internal technology.

Grabowski: It’s not translated, so is it some sort of visual or facet format where you grabbed the info out of the other CAD system?

Staples: No, it doesn’t use facets, because you actually treat them like b-reps. I think the easiest thing to think of is that the b-rep from the other CAD system is embedded inside our assembly, in a way that’s not visible to the user.

There is some intermediary geometry inside the assembly that’s managing that. When the originating system changes the model, then the internal b-rep changes.

Grabowski: Is this a function of Parasolid?

Staples: No, not particularly.

Grabowski: Where you say that it works with NX and SolidWorks, they both have Parasolid in common.

Staples: That is going to be your most reliable path, because they’re using the same format. But I would say that broadly it doesn’t matter what format you’re importing.

Grabowski: From the software launch video, it looks like Solid Edge interacts quite a bit with the imported object -- through handles, mates, constraints, and so on.

Staples: From the end users’ standpoint, they won’t be able to tell the difference between this or if they are using a Solid Edge file. It’s like you’re assembling a part file. Users won’t really be able to tell the difference other than it’s flagged in Pathfinder slightly differently. You hit the update links button to update the CAD Direct-linked file.

Grabowski: Then this leads me to the question of how the associative links are created and maintained?

Staples: We treat it very much like native solid geometry, which I think is probably the easiest way to think of it. This isn’t exactly technically correct, but it’s close enough. Solid Edge has a thing called “internal components,” which are part files embedded in the assembly. They’re treated just like an external component, but they never appear on disk.

You were talking about OLE before, where you used to have the notion of embedded or linked Excel files. Solid Edge has the ability to embed part files. This is largely the same. The body is available to us, the facets are available to us. We just don’t need a file on disk to deal with it.

Grabowski: I’m trying to understand how the link works for updates. If the external part is updated in the other CAD system, then there is some notification that this is happening. Where can that other CAD system be -- on the same network?

Staples: It will be like a link. That link in Windows can be anywhere, as long as it’s a fully resolvable, qualified path name. It wouldn’t necessarily have to be on your local drive as long as it’s a file system link that we can understand and run through, it would know the information.

Grabowski: So the source CAD system does not have to be available. Because Visio translators need to have Visio, they actually launch Visio in the background to do the translation.

Staples: The source CAD system does not have to be available now with CAD Direct.

Let’s take it even further with a diesel engine in a locomotive. You get the engine from Cummings or somebody, and you do not want to create 2,000 part files on your disk for that engine, because honestly you don’t care about the 2000 part files. You just care about the engine.

And yet you also don’t necessarily want to treat it like a part per say, because it’s not. It has moving parts. It’s a real thing.

And so our internal components let you take either a part or subassembly and put it in your assembly, and it acts just like the same thing. There aren’t any external files made, and so that actuator or that engine fully exists within the assembly in what’s called an internal component. It has structure in Pathfinder [model tree], you can see how it’s composed. You can articulate the parts, but you don’t have all that gloop on disk or in your PDM [product data management] system to manage. It’s treated like a part that came along for the ride.

Grabowski: So ‘gloop’ is a technical term then?

Staples: It is. I’m glad you recognize that. I’ve been using that since the ’90s as well.

Improved: Convergence Modeling

Convergent modeling from Siemens lets you mix and match solids and meshes in a single model. (Dassault has in its ACIS kernel something similar.) Convergent modeling lets you interact with meshes imported from scans (and other non-CAD sources) with solids (b-reps).

During the launch video, we saw a solids cutout added to a mesh handle, followed by an array of solids in the mesh and a Boolean operation to cut a hole. See figure below.

Grabowski: You’ve been working on hybrid modeling for a number of years now, as an offshoot of Parasolid. With this new release of Solid Edge, have you arrived at doing all that hybrid modeling needs to do? Or is there is there more to develop?

Staples: Let me answer that in two parts. Typically, we have been using the term ‘Convergent Modeling’, which is the Siemens term for the merger between facets and b-reps.

And yes, it’s enabled by Parasolid technology, but it’s not a part of our Parasolid modeling kernel. So it is something unique to Siemens and not necessarily available when you license Parasolid.

Grabowski: That’s like synchronous technology then.

Staples: Yes, it’s exactly like synchronous technology [in that ST cannot be licensed even when you license the Parasolid kernel].

You’re never complete, but I’d say we’re very close to completion. The big nut to crack was Booleans. In the past, when you did a Boolean between a b-rep and a facet mesh, the result would be that everything became facets, whereas now everything stays in its native form.

So when you do a Boolean between a b-rep and a facet, you end up with all the b-reps staying b-reps, and all the facets staying facets. It’s super efficient in terms of the way it’s done and stored. I do feel like it’s closure to the story we’ve been building over the last couple years.

Grabowski: I’m not super familiar with what else you’ve done in Convergence Modeling. Do you also convert facet meshes to b-reps?

Staples: We do have some facet mesh to b-rep conversion as part of our reverse engineering. In terms of functionality, it’ll find planes and cylinders, and cones, and so on.

The other thing we do that’s really cool and unique is that we can do almost all operations on faceted models with Synchronous Technology: move facets, we can round edges, we can do shells or thin walls -- so we don’t care whether they are facets or b-reps or a combination of the two.

I do think it’s a final frontier here, because meshes for a long time were the domain of the film industry and character modeling.

Grabowski: What happens when a hybrid part is exported to another CAD system?

Staples: It is all converted to meshes before being exported.

New: Point Clouds

Grabowski: Point clouds, are they new to 2022?

Staples: They are. We had done a prototype of this a year or two ago.

What we mean by point clouds? So it’s been possible to have lots of points in Solid Edge for a very long time, but they had to be displayed as triangles or b-reps. Now they stay points.

When you scan a plant, each point carries the color and spatial [x,y,z] location, and so you literally have at a minimum millions of points and sometimes billions of points. During rotation, Solid Edge renders them in real time at high speed.

That’s the thing that’s so interesting and is still amazing to me: that the points are so dense that you can even zoom in and it still looks good. It’s just amazing, the density of these point clouds. This is kind of ‘secret sauce science’ stuff. And that’s also the technical term, by the way.

Grabowski: The part I found interesting was you taking a measurement between a solids component and part of the point cloud. So I was curious: where on the point cloud is that measurement taken from?

Staples: So it’ll be taken from the point itself.

Grabowski: But which point? is it a rough measurement or? I’m curious about the accuracy.

Staples: Well, it’s only as accurate as the laser scan is accurate. But they are extraordinarily accurate. If you were to measure to a rusty water tank, you would be able to tell the difference between the rusty part and the not rusty part. I mean the lasers are super amazing these days.

- - -

I’ll close what’s-new in Solid Edge 2022 by describing one more feature that I found interesting: component colorization. See figure below.

To color parts, you assign colors to properties. This lets you visually identify which supplier or designer made the part, or the materials from which they were made. Siemens calls this “dynamic visualization.”

What Ralph Grabowski Thinks

Solid Edge 2022 is a remarkable upgrade, with some catch-up features (I’m looking at you, point clouds and Xcelerator Share) but also some really important new technologies, like the solids-mesh editing and CAD Direct.

Blogger Matt Lombard feels Siemens is aiming Solid Edge at big engineering: “There’s a lot of stuff aimed at plant design, large assemblies, fluid flow processing, framing, and piping. See the theme?”

solidedge.siemens.com/en/pages/solid-edge-2022/

And in Other News

LEDAS Group explains its rationale to buying software licenses: ledas.com/post/883-to-grow-rd-ledas-invests-in-many-more-software-licenses/

- - -

C3D Labs describes how it made its C3D Vision module up to 60% faster: c3dlabs.com/en/blog/products/update-to-c3d-vision-renderer-improves-performance-by-60/

- - -

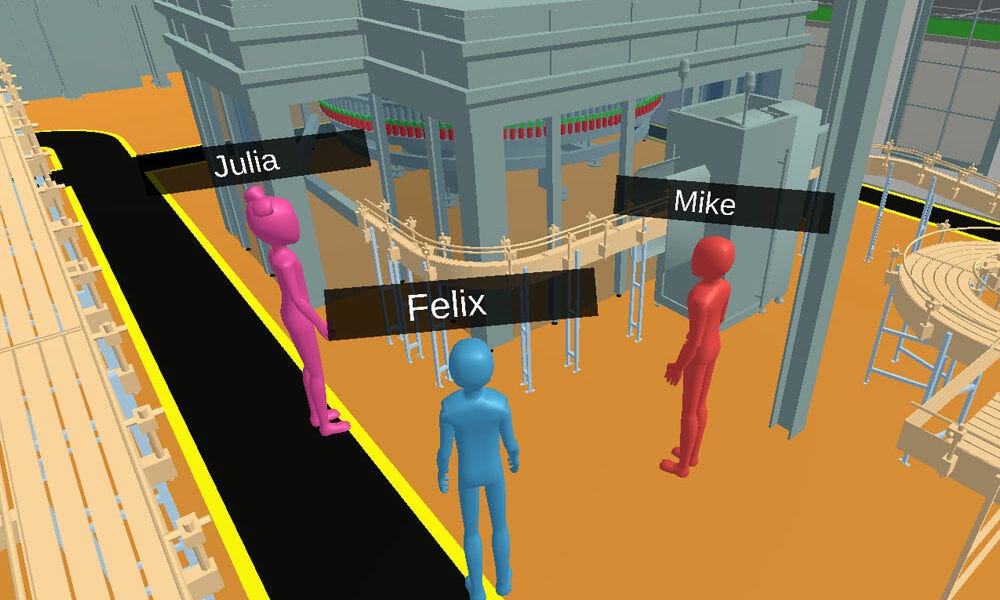

CAD Schroer updates its factory and plant design software M4 PLANT to version 7.1 with access to augmented and virtual reality.

For more information and to download the 30-day free trial, go to cad-schroer.com/news/news-releases/factory-layout-and-plant-design-version-7-1.

- - -

Windows 11 became available for download last week. There was one prime reason for Microsoft to invent a Windows 11: to force corporations to replace 11-“incompatible” hardware with new gear, boosting the profits of the HPs and Dells of the world. Today's hardware pretty much lasts forever (well, a decade or two anyhow), which is a problem for hardware makers, so we can think of 11 as hardware on subscription.

- - -

Here are some of the posts that appeared recently on my WorldCAD Access blog:

Guest editorial: Using Asynchronous Communication in CAD

The best reactions: Facebook's new surveillance sunglasses

You can subscribe to the WorldCAD Access blog’s RSS feed through Feed Burner at feeds.feedburner.com/WorldcadAccess.

Letters to the Editor

Re: A.I.’s Fatal Flaw

I’ve said for a long time that the only difference between human intelligence and machine intelligence is that humans make random mistakes. That is only partly tongue-in-cheek.

- Owen Wengerd, ManuSoft

The editor replies: It is random mistakes (chaos) that makes progress possible. Think penicillin and sticky notes.

- - -

It should be mentioned that any article on A.I. instantly becomes hilarious when you replace the capital “I” with a lowercase “L.” E.g.:

How dangerous is Al? Can Al ever be stopped?

Can Al turn my savings into millions?

Our extensive use of Al to make our product better failed miserably.

Etc.

- Matt Stachoni

The editor replies: Eliza should’ve been named Al!

- - -

The reader reaction to my editorial in the August issue of isicad at isicad.ru/ru/articles.php?article_num=22001 motivated me to pay greater attention to other articles related to A.I., some of them which I translated and published at isicad.ru, including your article, “A.I.’s Fatal Flaw”; see http://isicad.ru/ru/articles.php?article_num=22031.

Then, in my most recent editorial in September, “The Artificial Problem of Artificial Intelligence,” I made some more comments on the topic. Two notes:

Some of my judgments and feelings are due to my many years of active work in an academic A.I. lab where we dealt with expert systems, machine understanding of natural language, sub-definite calculations (something more general than today’s generative design), and more.

On the one hand, I do not like widely spread today’s hype and vulgar simplification of problems. On the other, I do believe that much more fundamental R&D can implement much more in the area of A.I. advances.

From what I have heard, BricsCAD applies machine learning for classification of BIM elements based on geometry to understand what is a wall and what is a window, as well as analyzing whether parts can be produced as sheet metal.

The title on isicad’s September cover is “A.I. Engineer.” In Russian at least, “И. И. Инженер” is definitely interpreted as “initials + last name.”

- David Levin

- - -

Concerning the 4th statement, systems with natural intelligence have a standard set of basic goals of functioning, survival and procreation. They develop behavioral goals by analyzing the state of their own body and the environment. In the process of achieving various goals of behavior, they solve many different problems.

It would be strange if an artificial system, which does not have the basic goals of functioning at all and receives goals of behavior from the outside, would be a complete analogue. We can only talk about a way to solve specific problems.

- Sergey Perovskiy (on isiscad)

Notable Quotable

“The rule of the tech economy is that everything must eventually get bought by one of the monopolies.”

- Paris Marx

Thank You, Readers

Thank you to readers who donate towards the operation of upFront.eZine:

Warren Cross: “I’ve been a faithful reader for almost 1/3 of my 75 years. While I am no longer an instructor of computer-aided drafting and design, I still enjoy learning of the expansion and of the capabilities of design software. AutoCAD 2. 5, I hardly remember you. Thanks for your many contributions and books to the industry.”

Cary Concrete Products: “I am getting up to 96% retired, but still like reading some of your stuff, especially the less CAD-technical.”

To support upFront.eZine through PayPal.me, then I suggest the following amounts:

$25 for individuals > paypal.me/upfrontezine/25

$150 for small companies > paypal.me/upfrontezine/150

$750 for large companies > paypal.me/upfrontezine/750

Should Paypal.me not operate in your country, then please use www.paypal.com and use the account of grabowski@telus.net.

Or ask grabowski@telus.net about making a direct bank transfer through Wise (Transferwise).

Or mail a cheque (US$ or CDN$ only, please) to upFront.eZine Publishing, Ltd., 34486 Donlyn Avenue, Abbotsford BC, V2S 4W7, Canada.

Contact!

upFront.eZine is published most Mondays. This newsletter is read by 4,700 subscribers in 70 countries. Read our back issues at www.upfrontezine.com.

Editor: Ralph Grabowski

Copy editor: Heather MacKenzie

Letter the editor are welcome at grabowski@telus.net. All letters sent to the editor are subject to publication, and may be edited for clarity and brevity.

Advertising starts at US$340 per two weeks. Download the media kit from upFront-Media-Kit.pdf. Contact grabowski@telus.net to discuss advertising.

To subscribe, click this link to sign up with with our mailer, Substack.

To change your address, send both your old and new email addresses to me at grabowski@telus.net.

To unsubscribe, click the Unsubscribe link at the end of this newsletter.

*4710

About

Copyright © 2021 by upFront.eZine Publishing, Ltd. All rights reserved.

Legal. All trademarks belong to their respective holders. “upFront.eZine,” “The Business of CAD,” “WorldCAD Access,” and “eBooks.onLine” are trademarks of upFront.eZine Publishing, Ltd. Translations and opinions expressed are not necessarily shared by upFront.eZine Publishing, Ltd. By accessing this newsletter in any manner, you agree to settle disputes within ten days of publication date by arbitration within the city limits of Abbotsford, British Columbia, Canada with the arbitrator selected by an agent acting on behalf of upFront.eZine Publishing, Ltd.

Our mailing address:

upFront.eZine Publishing, Ltd.

34486 Donlyn Avenue

Abbotsford BC

V2S 4W7